API vs EDI – Choosing the ideal solution for 3PL

Whether you're new to EDI integration or have been in EDI for years, you're reading this article because you're facing an EDI challenge and you're interested in using an API to help you solve it.

Maybe you're a logistics integrator and have just received your first order from a cross-border e-commerce retail giant. This is a milestone for your business - but with the excitement comes the requirement to conduct EDI transactions, and you don't have much time to implement EDI.

If you are involved in transport management systems (TMS), supply chain integration, e-commerce, logistics business process automation, enterprise resource planning (ERP) or any other practice area, you may find yourself straddling the world of EDI and APIs. Your business needs to transact traditional EDI transactions as well as integrate with APIs. In this article, we'll discuss the differences and how to effectively leverage both as you expand your business.

Introduction to EDI

EDI (Electronic Data Interchange) became the standard for business communications around the time of the debut of the Value Added Network (VAN). The first cross-industry EDI specification was published in 1975, paving the way for companies to exchange data in a standardized format.

Originating in military logistics, EDI introduced data exchange standards to support the large volumes of goods transported during the Berlin Airlift in 1948. From the 1970s onwards, transport companies, the grocery and food industries, car manufacturers and large retailers began to adopt EDI.¹ Soon, large companies required all their suppliers and trading partners to implement EDI connections. The era of syntax-neutral, standards-based data exchange soon became firmly entrenched in mainstream business.

Leaders and followers

While EDI allowed large companies ('leaders') to reduce costs by eliminating paperwork, faxes and phone calls, it was expensive and complex for smaller companies ('followers') to implement. Leaders set guidelines, tests and communication channel requirements and require followers to transact with them according to the specifications defined by the leader. For new trading partners, EDI integration requires expensive software, powerful IT resources and the use of a dedicated VAN. to make matters worse, small companies have to implement separate EDI integrations for each large customer, as each uses a slightly different EDI standard

EDI helps companies reduce costs, increase speed, eliminate errors and improve inter-company relationships by replacing mail, fax and email in traditional document exchange. instead of manual transactions, EDI allows companies to automate their business.

EDI documents are transferred to an application on the recipient's computer and processing (translation) can begin immediately, without manual involvement. Purchase orders, invoices, advance shipping notices, bills of lading, customs documents, inventory reports, shipping status documents and payment documents are examples of documents that can be transferred via EDI.

With the advent of the Internet, new protocols offered an alternative to using VAN for the communication layer of EDI. As a result, a number of large EDI users developed their own online exchanges, using a Web-like markup language rather than rigid EDI documents. technologies such as XML, PEPPOL, cXML, OASIS and ebXML have had limited success in improving EDI.

How EDI works

It is impressive that it is possible to send such a small amount of data with so few characters in an EDI transaction.50 The standards developed many years ago focused on sending very high value content with a very small payload.

Business-prepared documents must be translated into EDI format using the appropriate segments and data elements. Specialist mapping expertise is required to define how your internal business data is to be associated with EDI data. Software is available to assist with X12 and XML EDI data conversion.

Every leader has their own EDI requirements. This creates much of the transactional complexity that exists in today's supply chain. Not only does each leader have their own requirements, but there is no guarantee that their guidelines will follow the standards set by the ANSI X12 standard.

EDI is usually divided into two different standards; X12 is widely adopted in North America and EDIFACT is fully utilised in Europe and Asia Pacific. These standards are used to provide a management model for how to conduct a transaction with another company. These standards are defined by the unique features that make EDI a reality. an EDI transaction consists of multiple paragraphs, elements, qualifiers and loops.

Edi Integration

By implementing an EDI cloud logistics system to help with the process and then choosing one party to be the leader, you can more easily manage the 3PL integration. Typically, it should be the 3PL provider, as their business stays the same as they work with many different brand manufacturers. 3PLs should specify their requirements and let the brand manufacturers build the integrations needed to meet those requirements.

Most brand manufacturers using legacy EDI cloud logistics systems have built custom integration environments that are maintained by in-house teams of EDI experts, or have outsourced to a hosted service provider. In any case, this integration network is both complex and expensive to maintain. Most importantly, as your business continues to grow, scaling is a challenge.

Edi acts as a central point of integration for ERP or cloud logistics systems of record as well as 3PL. Connect to our platform once and leverage your existing 3PL and partner network to consolidate all your EDI providers into one hub.

What is APIs

API (Application Programming Interface) technology dates back to the 1940s, but modern APIs have their roots in the Internet, made possible by the REST (Representative State Transfer) architectural style, which created a framework for the architecture of the World Wide Web and established guidelines for creating stateless, reliable Web APIs.

REST addresses behavioral constraints, scalability, unified interfaces, and independent deployment and creates a layered architecture to facilitate caching, reduce latency, provide security and encapsulate legacy systems.

Developer building blocks

Developers can use the API to create complex processes and reuse code, rather than developing new code for each process. As a result, APIs act like building blocks, allowing development teams to deliver quickly and flexibly to enable faster supply chain integration. As an alternative to traditional EDI development tools, APIs allow companies to access web-based software to communicate with their trading partners.

The role of APIs

APIs exist to support integration by allowing applications, devices and servers to communicate with each other. APIs act as intermediaries between applications. APIs relay requests to applications and then return responses to the requester.

APIs convey machine-readable information, allowing work to be performed without human intervention. APIs can integrate with many different cloud logistics systems - such as customer relationship management (CRM) systems, databases, enterprise resource planning (ERP) systems and other types of cloud logistics systems - helping companies become more agile and -helping companies to become more agile and responsive to other organizations.

How the API works

HTTP methods are typically used to access resources via URL-encoded parameters and to transfer data using JSON or XML. A request for a resource's Uniform Resource Identifier (URI) triggers a response with a payload in HTML, XML or JSON format. methods such as GET, POST, PUT, PATCH and DELETE can be executed by the API using the HTTP protocol to perform create, read, update or delete operations. Unlike EDI, API transactions allow responses to contain hypertext links to relevant resources and reliable response details.

Multi-Carrier Transport API

The Multi-Carrier Transport API is a set of programming technologies that allow users to build customized carrier manifest solutions for ERP, WMS, e-commerce, marketing or any internal customer cloud logistics system.

The Multi-Carrier Transport API supports integration between transport carriers and an organization's business cloud logistics systems. It is a single API that seamlessly integrates with hundreds of carriers worldwide. Designed for any type of business with small to very large shippers.

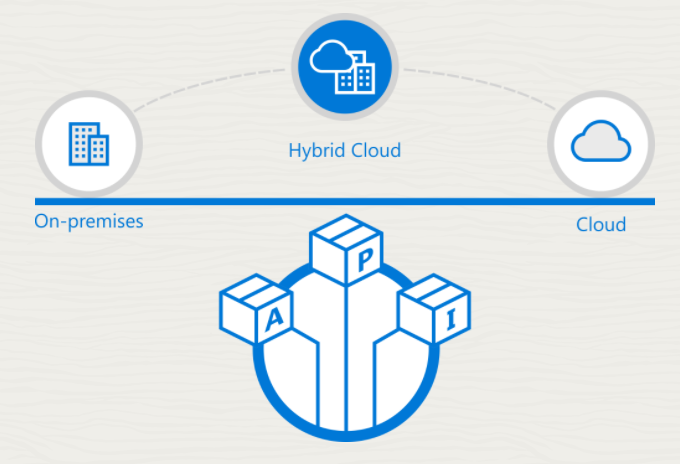

Multi-Carrier Shipping API is available locally and in the cloud

Simplify operations by integrating common shipping carrier functions into your business workflow

Save time by automating common processes such as rate and service selection, generating labels and exchanging data between information sources

Industry-standard, conforming to industry standards and compatible with developer tools.

Increased flexibility, providing organizations with greater flexibility by allowing programmers to integrate transport functions directly into your business cloud logistics systems.

Single API, all major carrier (small parcel, LTL, TL and freight forwarding) services are integrated with a single API call.

EDI vs API

Originally designed with standardization and automation in mind, EDI is an entrenched, code-based framework for business data exchange. It is notoriously difficult to implement, requiring significant development resources and sometimes months to get business partners to the level of integration required to do business. The reason for this complexity is the need for EDI experts to interpret EDI requirements. These requirements are different for each leader. If you are a follower who needs to integrate with a leader, then you need to understand how to read these requirements before you can start.

API technology was born in the Internet era with a unified interface and hypertext parameters. API technology allows for rapid development, high reliability and the ability to reuse components. For its part, API technology enables companies to automate many aspects of doing business with trading partners without the need for additional technical infrastructure. In supporting EDI integration, API technology offers advantages to development teams and is playing an increasing role in EDI integration strategies.

Advantages and disadvantages of EDI

Since its inception half a century ago, the "benefits" of EDI have helped to make the business world more efficient.

Secure communication with EDI integrated trading partners

Dynamic transmission of business documents

Transfer of information about payments or deliveries

EDI replaces telephone, mail, email and fax

Save time and costs, reduce errors and lower transaction costs compared to paper

For decades, the "drawbacks" of EDI have plagued companies and developers.

Complex integration and extended development time

Often requires EDI expertise

Difficult for companies with limited IT resources

EDI software needs to be integrated with business systems such as ERP

Different partners can have different versions of EDI transactions

Long integration times may delay vendor onboarding

Detailed information not included in EDI transaction responses

EDI integrations often require IT teams with experience in EDI As EDI documents can be transmitted using any method agreed by the sender and receiver, a variety of programming technologies are used - including modems (asynchronous and synchronous), email, AS1, AS2, AS4, OFTP, OFTP2, mobile EDI and others - as well as standardized Internet protocols.

Advantages and disadvantages of APIs

The 'benefits' of API technology depend on speed, flexibility, reusability and the use of modern tools.

Connectivity of different applications, systems, servers, data and software

Real-time feedback

Detailed information contained in API transaction responses

The self-service model allows for independent deployment

Ability to publish requirements to the Internet

Ability to reduce human coding errors

Use of common Internet protocols, including HTTP and HTTPS

Greater programming familiarity for modern development teams

Wide range of open source solutions

Use of reusable building blocks

Developers can make changes without affecting other services

Layered architecture helps with caching and reduces latency

Given that APIs allow for fast, agile and adaptable integration using modern development tools, the main disadvantage of APIs is that they are more unstructured than EDI. For example, endpoint names, authentication, architecture and documentation of integration requirements for transaction types will vary from one trading partner to another.

Open source and reusable tools allow API developers to develop and customize projects. APIs provide continuous connectivity to Web applications, enabling self-service, real-time feedback, documentation, layered security, authentication and Web publishing requirements.

Electronic Data Interchange

EDI transactions use proprietary communication channels and payload frameworks. 997 responses return acceptance/rejection only, with no error descriptions or details.

API

API transactions are built using modern transport protocols and payloads. Guidelines and requirements are machine-readable and published to the web. Responses are robust and provide transaction details or error explanations.

The need for EDI

Is it possible to replace EDI completely with API technology? In theory, yes, two companies could decide to do so. However, when weighing EDI against API technology, it is unrealistic to think that you can only transact in one format or the other.

A handful of retailers (led by Walmart and Amazon) now offer an API that allows trading partners to send transactions without EDI software. But these cases are the exception. Most large cross-border B2Cs still require EDI transactions.

EDI is not going away in the foreseeable future, as this sea change will require all trading partners in the supply chain to upgrade their technology to handle API transactions. This is too much to ask of the supply chain, which means that EDI is here to stay.

If you do business with partners who need EDI, you have no choice. The only question is how you will integrate your cloud logistics systems with EDI. The modern way is to use API technology to connect your cloud logistics systems to the EDI system.

Thanks to APIs, the path to EDI integration is easier than ever.

Moving to APIs

The good news is that an increasing number of large companies are developing API options for supply chain integration or plan to do so soon. The reasons they are moving to API-based integration are as numerous as the benefits of API technology itself: the

Self-service model

Ability to publish requirements on the internet

Easy authentication

Real-time feedback

Documentation

Iteration

Developer friendly

Modern tools and languages

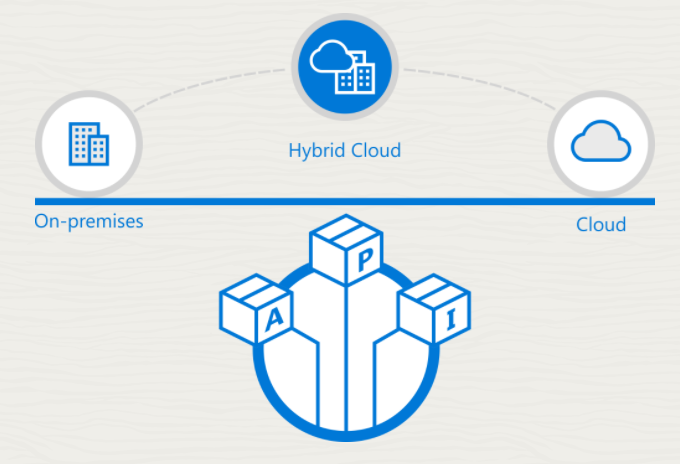

The ideal EDI cloud logistics system - APIs and EDI

The ideal EDI cloud logistics system would provide modern APIs for connecting to ERP, CRM and other internal cloud logistics systems. any participant in the supply chain could use the API technology to connect their business systems to the cloud solution and be able to send EDI transactions to any other company in the network.

The cloud solution will provide pre-built EDI connections for each company in the supply chain (retailers, manufacturers and all connected logistics and transport providers). The service will protect users from the complexity of EDI transactions as they are pre-built.

The ideal EDI cloud logistics system also allows users to utilise a combination of API and EDI technology. The benefit to the business is the ability to connect the company's internal cloud logistics systems to a modern infrastructure and handle legacy EDI requests through this modern system.

Thanks to this combination of APIs and pre-built EDI transactions, the time required to implement the cloud logistics system and join new trading partners will be significantly reduced.

Preview the ideal system here

Today, forward-thinking companies are already using the ideal EDI cloud logistics system. eTower is a cloud logistics system with a modern API to connect business systems and trading partners, making EDI integration simple.

The cloud logistics system is already being used by a number of operators and 3PL providers. Companies are using this cloud-based EDI platform to reduce complexity, speed up onboarding integration, reduce costs and use internal resources more efficiently.

Using this cloud logistics system, the time taken to onboard new trading partners has been reduced from months to days.

Find out more about the eTower EDI cloud logistics system.Whether you're new to EDI integration or have been in EDI for years, you're reading this article because you're facing an EDI challenge and you're interested in using an API to help you solve it.

Maybe you're a logistics integrator and have just received your first order from a cross-border e-commerce retail giant. This is a milestone for your business - but with the excitement comes the requirement to conduct EDI transactions, and you don't have much time to implement EDI.

If you are involved in transport management systems (TMS), supply chain integration, e-commerce, logistics business process automation, enterprise resource planning (ERP) or any other practice area, you may find yourself straddling the world of EDI and APIs. Your business needs to transact traditional EDI transactions as well as integrate with APIs. In this article, we'll discuss the differences and how to effectively leverage both as you expand your business.

Introduction to EDI

EDI (Electronic Data Interchange) became the standard for business communications around the time of the debut of the Value Added Network (VAN). The first cross-industry EDI specification was published in 1975, paving the way for companies to exchange data in a standardized format.

Originating in military logistics, EDI introduced data exchange standards to support the large volumes of goods transported during the Berlin Airlift in 1948. From the 1970s onwards, transport companies, the grocery and food industries, car manufacturers and large retailers began to adopt EDI.¹ Soon, large companies required all their suppliers and trading partners to implement EDI connections. The era of syntax-neutral, standards-based data exchange soon became firmly entrenched in mainstream business.

Leaders and followers

While EDI allowed large companies ('leaders') to reduce costs by eliminating paperwork, faxes and phone calls, it was expensive and complex for smaller companies ('followers') to implement. Leaders set guidelines, tests and communication channel requirements and require followers to transact with them according to the specifications defined by the leader. For new trading partners, EDI integration requires expensive software, powerful IT resources and the use of a dedicated VAN. to make matters worse, small companies have to implement separate EDI integrations for each large customer, as each uses a slightly different EDI standard

EDI helps companies reduce costs, increase speed, eliminate errors and improve inter-company relationships by replacing mail, fax and email in traditional document exchange. instead of manual transactions, EDI allows companies to automate their business.

EDI documents are transferred to an application on the recipient's computer and processing (translation) can begin immediately, without manual involvement. Purchase orders, invoices, advance shipping notices, bills of lading, customs documents, inventory reports, shipping status documents and payment documents are examples of documents that can be transferred via EDI.

With the advent of the Internet, new protocols offered an alternative to using VAN for the communication layer of EDI. As a result, a number of large EDI users developed their own online exchanges, using a Web-like markup language rather than rigid EDI documents. technologies such as XML, PEPPOL, cXML, OASIS and ebXML have had limited success in improving EDI.

How EDI works

It is impressive that it is possible to send such a small amount of data with so few characters in an EDI transaction.50 The standards developed many years ago focused on sending very high value content with a very small payload.

Business-prepared documents must be translated into EDI format using the appropriate segments and data elements. Specialist mapping expertise is required to define how your internal business data is to be associated with EDI data. Software is available to assist with X12 and XML EDI data conversion.

Every leader has their own EDI requirements. This creates much of the transactional complexity that exists in today's supply chain. Not only does each leader have their own requirements, but there is no guarantee that their guidelines will follow the standards set by the ANSI X12 standard.

EDI is usually divided into two different standards; X12 is widely adopted in North America and EDIFACT is fully utilised in Europe and Asia Pacific. These standards are used to provide a management model for how to conduct a transaction with another company. These standards are defined by the unique features that make EDI a reality. an EDI transaction consists of multiple paragraphs, elements, qualifiers and loops.

Edi Integration

By implementing an EDI cloud logistics system to help with the process and then choosing one party to be the leader, you can more easily manage the 3PL integration. Typically, it should be the 3PL provider, as their business stays the same as they work with many different brand manufacturers. 3PLs should specify their requirements and let the brand manufacturers build the integrations needed to meet those requirements.

Most brand manufacturers using legacy EDI cloud logistics systems have built custom integration environments that are maintained by in-house teams of EDI experts, or have outsourced to a hosted service provider. In any case, this integration network is both complex and expensive to maintain. Most importantly, as your business continues to grow, scaling is a challenge.

Edi acts as a central point of integration for ERP or cloud logistics systems of record as well as 3PL. Connect to our platform once and leverage your existing 3PL and partner network to consolidate all your EDI providers into one hub.

What is APIs

API (Application Programming Interface) technology dates back to the 1940s, but modern APIs have their roots in the Internet, made possible by the REST (Representative State Transfer) architectural style, which created a framework for the architecture of the World Wide Web and established guidelines for creating stateless, reliable Web APIs.

REST addresses behavioral constraints, scalability, unified interfaces, and independent deployment and creates a layered architecture to facilitate caching, reduce latency, provide security and encapsulate legacy systems.

Developer building blocks

Developers can use the API to create complex processes and reuse code, rather than developing new code for each process. As a result, APIs act like building blocks, allowing development teams to deliver quickly and flexibly to enable faster supply chain integration. As an alternative to traditional EDI development tools, APIs allow companies to access web-based software to communicate with their trading partners.

The role of APIs

APIs exist to support integration by allowing applications, devices and servers to communicate with each other. APIs act as intermediaries between applications. APIs relay requests to applications and then return responses to the requester.

APIs convey machine-readable information, allowing work to be performed without human intervention. APIs can integrate with many different cloud logistics systems - such as customer relationship management (CRM) systems, databases, enterprise resource planning (ERP) systems and other types of cloud logistics systems - helping companies become more agile and -helping companies to become more agile and responsive to other organizations.

How the API works

HTTP methods are typically used to access resources via URL-encoded parameters and to transfer data using JSON or XML. A request for a resource's Uniform Resource Identifier (URI) triggers a response with a payload in HTML, XML or JSON format. methods such as GET, POST, PUT, PATCH and DELETE can be executed by the API using the HTTP protocol to perform create, read, update or delete operations. Unlike EDI, API transactions allow responses to contain hypertext links to relevant resources and reliable response details.

Multi-Carrier Transport API

The Multi-Carrier Transport API is a set of programming technologies that allow users to build customized carrier manifest solutions for ERP, WMS, e-commerce, marketing or any internal customer cloud logistics system.

The Multi-Carrier Transport API supports integration between transport carriers and an organization's business cloud logistics systems. It is a single API that seamlessly integrates with hundreds of carriers worldwide. Designed for any type of business with small to very large shippers.

Multi-Carrier Shipping API is available locally and in the cloud

Simplify operations by integrating common shipping carrier functions into your business workflow

Save time by automating common processes such as rate and service selection, generating labels and exchanging data between information sources

Industry-standard, conforming to industry standards and compatible with developer tools.

Increased flexibility, providing organizations with greater flexibility by allowing programmers to integrate transport functions directly into your business cloud logistics systems.

Single API, all major carrier (small parcel, LTL, TL and freight forwarding) services are integrated with a single API call.

EDI vs API

Originally designed with standardization and automation in mind, EDI is an entrenched, code-based framework for business data exchange. It is notoriously difficult to implement, requiring significant development resources and sometimes months to get business partners to the level of integration required to do business. The reason for this complexity is the need for EDI experts to interpret EDI requirements. These requirements are different for each leader. If you are a follower who needs to integrate with a leader, then you need to understand how to read these requirements before you can start.

API technology was born in the Internet era with a unified interface and hypertext parameters. API technology allows for rapid development, high reliability and the ability to reuse components. For its part, API technology enables companies to automate many aspects of doing business with trading partners without the need for additional technical infrastructure. In supporting EDI integration, API technology offers advantages to development teams and is playing an increasing role in EDI integration strategies.

Advantages and disadvantages of EDI

Since its inception half a century ago, the "benefits" of EDI have helped to make the business world more efficient.

Secure communication with EDI integrated trading partners

Dynamic transmission of business documents

Transfer of information about payments or deliveries

EDI replaces telephone, mail, email and fax

Save time and costs, reduce errors and lower transaction costs compared to paper

For decades, the "drawbacks" of EDI have plagued companies and developers.

Complex integration and extended development time

Often requires EDI expertise

Difficult for companies with limited IT resources

EDI software needs to be integrated with business systems such as ERP

Different partners can have different versions of EDI transactions

Long integration times may delay vendor onboarding

Detailed information not included in EDI transaction responses

EDI integrations often require IT teams with experience in EDI As EDI documents can be transmitted using any method agreed by the sender and receiver, a variety of programming technologies are used - including modems (asynchronous and synchronous), email, AS1, AS2, AS4, OFTP, OFTP2, mobile EDI and others - as well as standardized Internet protocols.

Advantages and disadvantages of APIs

The 'benefits' of API technology depend on speed, flexibility, reusability and the use of modern tools.

Connectivity of different applications, systems, servers, data and software

Real-time feedback

Detailed information contained in API transaction responses

The self-service model allows for independent deployment

Ability to publish requirements to the Internet

Ability to reduce human coding errors

Use of common Internet protocols, including HTTP and HTTPS

Greater programming familiarity for modern development teams

Wide range of open source solutions

Use of reusable building blocks

Developers can make changes without affecting other services

Layered architecture helps with caching and reduces latency

Given that APIs allow for fast, agile and adaptable integration using modern development tools, the main disadvantage of APIs is that they are more unstructured than EDI. For example, endpoint names, authentication, architecture and documentation of integration requirements for transaction types will vary from one trading partner to another.

Open source and reusable tools allow API developers to develop and customize projects. APIs provide continuous connectivity to Web applications, enabling self-service, real-time feedback, documentation, layered security, authentication and Web publishing requirements.

Electronic Data Interchange

EDI transactions use proprietary communication channels and payload frameworks. 997 responses return acceptance/rejection only, with no error descriptions or details.

API

API transactions are built using modern transport protocols and payloads. Guidelines and requirements are machine-readable and published to the web. Responses are robust and provide transaction details or error explanations.

The need for EDI

Is it possible to replace EDI completely with API technology? In theory, yes, two companies could decide to do so. However, when weighing EDI against API technology, it is unrealistic to think that you can only transact in one format or the other.

A handful of retailers (led by Walmart and Amazon) now offer an API that allows trading partners to send transactions without EDI software. But these cases are the exception. Most large cross-border B2Cs still require EDI transactions.

EDI is not going away in the foreseeable future, as this sea change will require all trading partners in the supply chain to upgrade their technology to handle API transactions. This is too much to ask of the supply chain, which means that EDI is here to stay.

If you do business with partners who need EDI, you have no choice. The only question is how you will integrate your cloud logistics systems with EDI. The modern way is to use API technology to connect your cloud logistics systems to the EDI system.

Thanks to APIs, the path to EDI integration is easier than ever.

Moving to APIs

The good news is that an increasing number of large companies are developing API options for supply chain integration or plan to do so soon. The reasons they are moving to API-based integration are as numerous as the benefits of API technology itself: the

Self-service model

Ability to publish requirements on the internet

Easy authentication

Real-time feedback

Documentation

Iteration

Developer friendly

Modern tools and languages

The ideal EDI cloud logistics system - APIs and EDI

The ideal EDI cloud logistics system would provide modern APIs for connecting to ERP, CRM and other internal cloud logistics systems. any participant in the supply chain could use the API technology to connect their business systems to the cloud solution and be able to send EDI transactions to any other company in the network.

The cloud solution will provide pre-built EDI connections for each company in the supply chain (retailers, manufacturers and all connected logistics and transport providers). The service will protect users from the complexity of EDI transactions as they are pre-built.

The ideal EDI cloud logistics system also allows users to utilise a combination of API and EDI technology. The benefit to the business is the ability to connect the company's internal cloud logistics systems to a modern infrastructure and handle legacy EDI requests through this modern system.

Thanks to this combination of APIs and pre-built EDI transactions, the time required to implement the cloud logistics system and join new trading partners will be significantly reduced.

Preview the ideal system here

Today, forward-thinking companies are already using the ideal EDI cloud logistics system. eTower is a cloud logistics system with a modern API to connect business systems and trading partners, making EDI integration simple.

The cloud logistics system is already being used by a number of operators and 3PL providers. Companies are using this cloud-based EDI platform to reduce complexity, speed up onboarding integration, reduce costs and use internal resources more efficiently.

Using this cloud logistics system, the time taken to onboard new trading partners has been reduced from months to days.

Find out more about the eTower EDI cloud logistics system.

评论

发表评论